[ad_1]

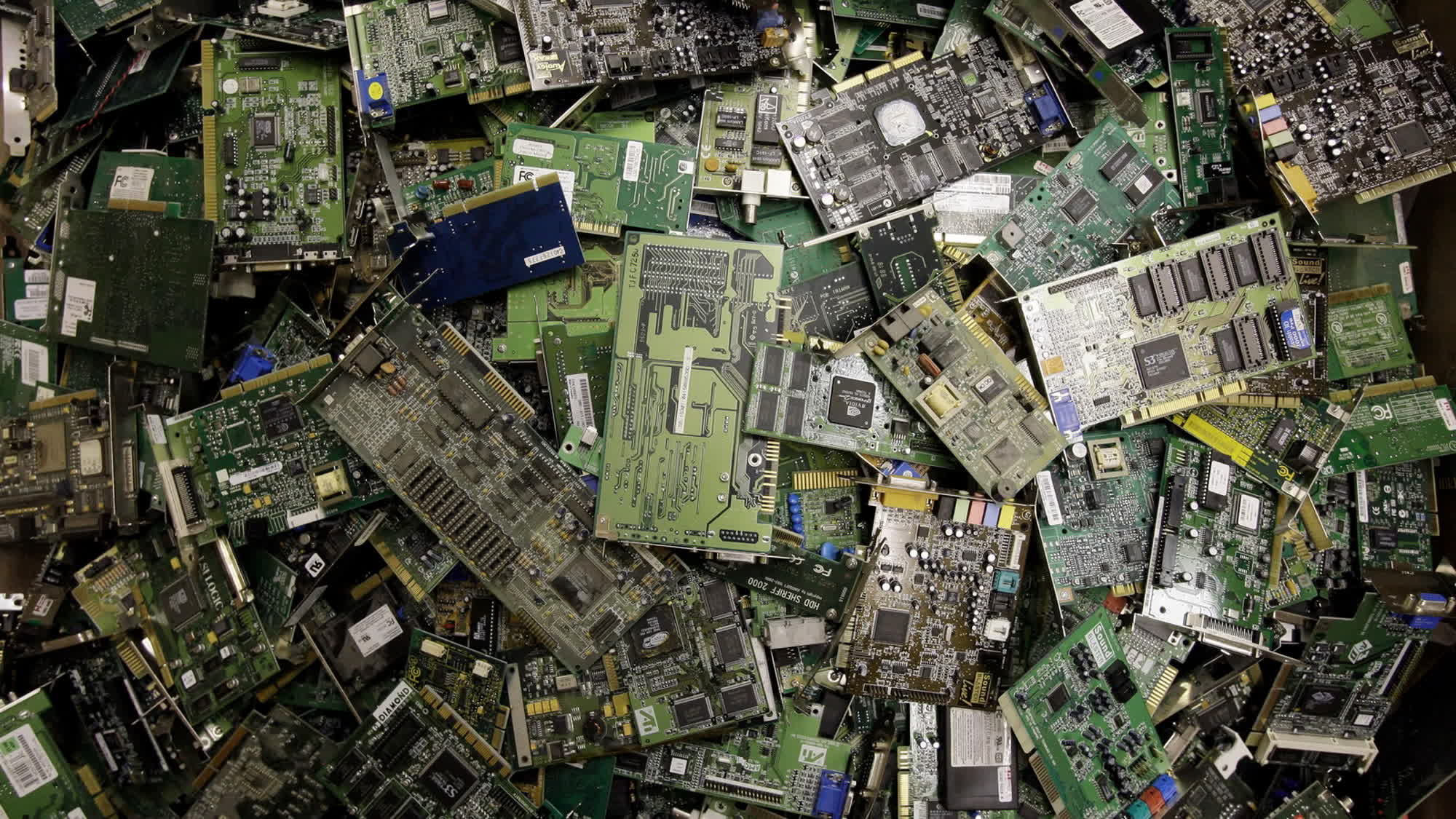

A scorching potato: Printed circuit boards are ubiquitous; they’re utilized in almost all digital units and represent a good portion of the digital waste accumulating in landfills. A brand new polymer-based materials may render PCBs rather more environmentally pleasant and facilitate countless recycling.

Researchers on the College of Washington have introduced the event of a brand new kind of PCB with considerably larger recycling potential than conventional printed circuits. Using cutting-edge sustainable polymers, these new PCBs have the potential to handle a considerable portion of the world’s e-waste points if broadly adopted.

Conventional PCBs, designed to deal with and join chips, transistors, and different digital elements, encompass layers of skinny glass fiber sheets coated in exhausting plastic and laminated with copper. The problem lies in separating the plastic elements from the glass, resulting in PCBs usually ending up in landfills, with particular person digital elements remaining unused for future purposes.

Present strategies of PCB recycling contain burning every thing to extract priceless supplies like copper and gold. This course of is usually carried out in growing nations, and poses well being dangers because of poisonous fumes. The UW researchers have launched vitrimer, a kind of polymer, to create their “vitrimer printed circuit boards” (vPCBs), which exhibit distinctive recycling properties when mixed with a selected natural solvent.

First developed in 2015, Vitrimer polymers have the flexibility to rearrange and type new bonds on the molecular degree when uncovered to particular circumstances, comparable to warmth at a exact temperature. In accordance with the researchers, Vitrimer-based vPCBs can rework right into a “jelly-like” substance in a solvent with out compromising their basic construction and will be recycled “repeatedly” with minimal materials loss.

When vitrimer is transformed into jelly, the digital elements turn out to be simply recoverable and reusable. Recycled vPCBs keep “high-quality” traits in comparison with recycled standard plastics. With these new vPCBs, the UW scientists managed to get better 98 % of the vitrimer polymer, 100% of the glass fiber, and 91 % of the solvent used throughout the recycling course of.

UW assistant professor Vikram Iyer highlighted how PCBs represent a good portion of the mass and quantity in digital waste. Whereas they’re designed to face up to warmth and chemical components, that are important for creating sturdy client merchandise, they pose challenges for recycling. vPCBs possess digital properties just like these of standard plastic PCBs however are significantly simpler to disassemble for creating new circuit boards.

In accordance with the researchers, vPCBs may doubtlessly cut back world warming by 48 % and reduce carcinogenic emissions by 81 %. Nonetheless, there are “important hurdles” to beat earlier than adopting this novel know-how. Governments would wish to implement “sturdy” laws to implement the brand new recycling techniques, compelling corporations to “design and optimize” supplies with sustainability targets in thoughts from the outset.

[ad_2]

Source link

/cdn.vox-cdn.com/uploads/chorus_asset/file/25524175/DSCF8101.jpg)